Off-the-rack clothes seldom fit perfectly, but with a little practice, you can usually eliminate the alterations fee. We'll begin with the materials you'll need to get started on your alterations.

Tools: scissors, tape measure, steam iron and ironing board, sleeve board, pressing cloth, sponge, mirror, straight pins, yardstick or skirt marker, sewing needles, sewing machine, pinking shears, seam ripper, pencil.

Materials: white vinegar; ribbon, lace, or bias seam binding, or wide bias seam tape; thread, fabric as necessary, paper.

Time: 1 hour or more, depending on alteration needed.

Rehemming

The most common problem with new clothes is the hem -- too short, too long, or uneven. Remove the old hem and press out the crease with a steam iron. If you're lengthening the garment and the old crease shows, sponge the crease with white vinegar and press it with a damp pressing cloth. Then put the garment on.

For the best results, work with a helper to mark the new hem. Stand in front of a mirror, in good light. Have your helper mark the new hem with straight pins at the desired point; keep pins close together. To make sure all pins are placed correctly, measure from the floor up with a yardstick or a skirt marker. Stand straight and turn slowly as your helper marks the new hem.

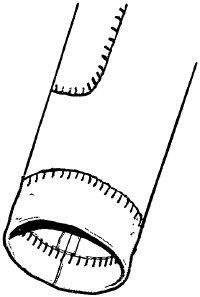

Take the garment off and set it on an ironing board, wrong side out. Turn the fabric up at the marked hemline and press it firmly to crease the new hem; remove the pins as you go. If you're hemming sleeves or pants legs, use a sleeve board as necessary to press the hem. Make sure the hem is plainly creased all around the garment.

Leaving the hem turned up, adjust the hem allowance as necessary to make an even hem, about the same width as the old one. For most garments, 1 to 2 inches is a good width for hems -- use 1-inch hems for sleeves or pants legs, 2-inch hems for skirts or jackets. Measure up from the crease into the hem allowance and trim the hem to the correct width all around.

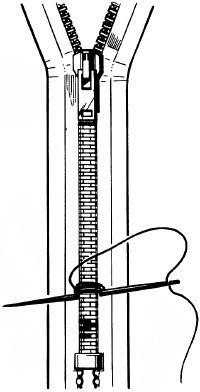

Before stitching the hem into place, you must finish the edge of the fabric if it is raw. For fabrics that don't ravel much, straight-stitch along the edge of the hem on a sewing machine, 1/4 inch from the edge; pink the edge with a pinking shears. For lightweight woven fabrics, turn the raw edge under 1/4 inch and straight-stitch it. For fabrics that ravel easily, straight-stitch along the edge of the hem, 1/4 inch from the edge; overcast the edge by hand or with a zigzag machine stitch. For loosely woven fabrics or where you want to avoid bulk, finish the raw hem edge with seam binding; use ribbon or lace binding for straight hems, bias binding for curved or flared hems. Overlap the binding half its width over the raw edge; straight-stitch it into place.

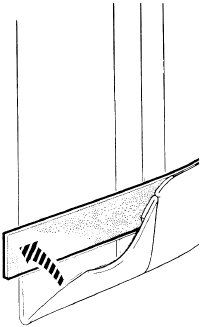

If you're letting the old hem down and there's less than 1 inch of hem allowance for the new hem, finish the raw edge with a facing of wide bias seam tape. Lay the tape along the evenly trimmed edge of the hem allowance, right sides together and outside edges flush. Straight-stitch the tape into place 1/4 inch from the edge; be careful not to stretch the tape. Then turn the tape up so the raw edges are underneath it, and press the seam open.

If the hem has a considerable curve or flare, pull in excess fullness before finishing the raw edge, to make sure the new hem will lie flat. Adjust the sewing machine to loosen upper thread tension and increase stitch length. On the right side of the hem allowance, straight-stitch along the hem edge, 3/8 inch from the raw edge. Then, with the right side of the hem allowance up, pull the bobbin thread with one hand and gather the fabric to the required fullness with the other. Check the gathered hem for proper fit before stitching it.

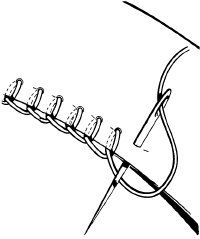

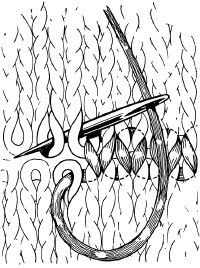

When the hem is properly trimmed and finished, stitch it into place. Stitch by hand, using matching thread. For most garments, use the hemming stitch; working from right to left, take a stitch in the hem edge and then catch one or two threads in the garment. For a strong hem in children's clothes or knits, use the catchstitch; work from left to right, catching one or two threads in the hem edge and then in the garment. For turned and stitched hems in lightweight woven fabrics, use the slipstitch; working from right to left, stitch along the hem fold, catching a thread of the garment periodically. Fasten the ends of the hem securely with small knots.

Refitting

Almost all other alterations are made to deal with clothes that are either too tight or too loose. Unless the size is drastically wrong, this is usually fairly easy to accomplish.

Letting out: If there is sufficient seam allowance, you can often solve the problem of tightness by opening the seams and restitching them closer to the raw edges. Sometimes it may be feasible to insert panels of extra fabric to provide additional width or length.

Where the garment is cut to fit closely, tightness is difficult to correct, because there's no extra fabric. If a sleeve is too tight around the shoulder and upper arm, it usually isn't possible to loosen it. The best solution for a shirt or dress may be to remove the sleeve altogether and finish the armhole with a facing.

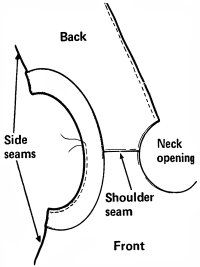

To remove a sleeve, use a seam ripper to carefully remove all the seams that join the sleeve to the garment body. Open the side seam of the garment to the waist. Open the garment flat. Using the garment's sleeve opening as a pattern, trace the curve of the opening onto facing material; cut a piece of fabric 2 inches wide to follow the entire curve. Use a fabric of the same weight as the garment, in a matching or coordinating color; if the garment had long sleeves, cut the new facing from the sleeve material.

Finish the outside edge of the curved facing by turning the edge under 1/4 inch; straight-stitch along the turned edge on the sewing machine. Place the facing over the outside (right side) of the opened armhole, right sides together, to match the curve exactly, and pin it into place. Straight-stitch the facing to the armhole opening, leaving a 5/8-inch seam allowance.

After stitching the facing onto the armhole, clip into the seam allowance every 1 to 2 inches around the armhole, cutting close to, but not into, the seam. Restitch the side seam of the garment, following the old seam line exactly. Turn the facing to the inside of the garment, press it down, and pin it into place. Sew the facing to the inside of the garment by hand, using a hemming stitch; be careful to catch only one thread of the garment fabric.

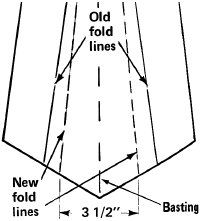

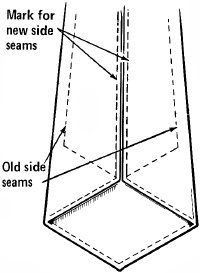

Taking in: Making clothes tighter is easier than letting them out. To get a really good fit, remove the stitching from the seam involved; try the garment on and have a helper pin or baste the seams in the correct position. Cut off excess fabric, if necessary; then restitch the seams as marked, curving them very gradually into the line of the old seams. Don't just take in all existing seams -- if the garment fits unevenly, a poorly made alteration will not correct the problem. Remove all seams affected, try on, and pin or baste; restitch seams in the new position and adjust as necessary.

To take in a shirt or the bodice of a dress, you may have to remove the sleeves and adjust the side seams. In this case, to prevent changing the shape of the sleeves, open the side seam to the waist and make a paper pattern of the armhole, as above; mark the sleeves as you remove them so you'll be able to replace them correctly. After adjusting the garment's seams, use the pattern to cut the armhole to its old shape, as necessary. Then restitch the side seams and replace the sleeves.

On the next page, we'll give step-by-step instructions on how to custom-fit a pair of pants.